In electroplating, workpieces are immersed in an electrolytic bath, and electrical voltage deposits the desired coating onto the workpiece. Galvano Helbling specializes in small series and individual parts, providing excellent quality with proven expertise.

Chrome

Our chrome plating combines high corrosion resistance with a striking appearance. It is used in both industrial and decorative applications. We offer bluish-white layers in variations from matte to high gloss.

– Advantages

High abrasion resistance and hardness Ability to handle large series with short turnaround times.

– Applications

- Medical devices

- Machine parts

- Housings for various industries

- Fixtures

- Motorcycle parts

- Decorative items

– Properties

Hardness: 800–1000 HV depending on layer thickness

Layer thickness: up to 5 μm

Color: Bluish-white, gloss depending on intermediate layers and base material

Zinc

Galvanic zinc plating effectively protects your products against corrosion. Particularly for iron materials, the zinc layer is a cost-effective solution. Available for both rack and barrel plating.

– Advantages

Post-treatment options: blue, yellow, black, or olive passivation Hydrogen embrittlement relief after plating available

Adheres to all zinc-related standards.

– Applications

- Mechanical engineering

- Automotive industry

- Construction and fittings

- Agricultural and construction machinery

– Properties

Hardness: approx. 200 HV

Layer thickness: 5–25 μm

Corrosion resistance: 100–300 hours to white rust (dependent on passivation)

Temperature resistance: up to 220°C

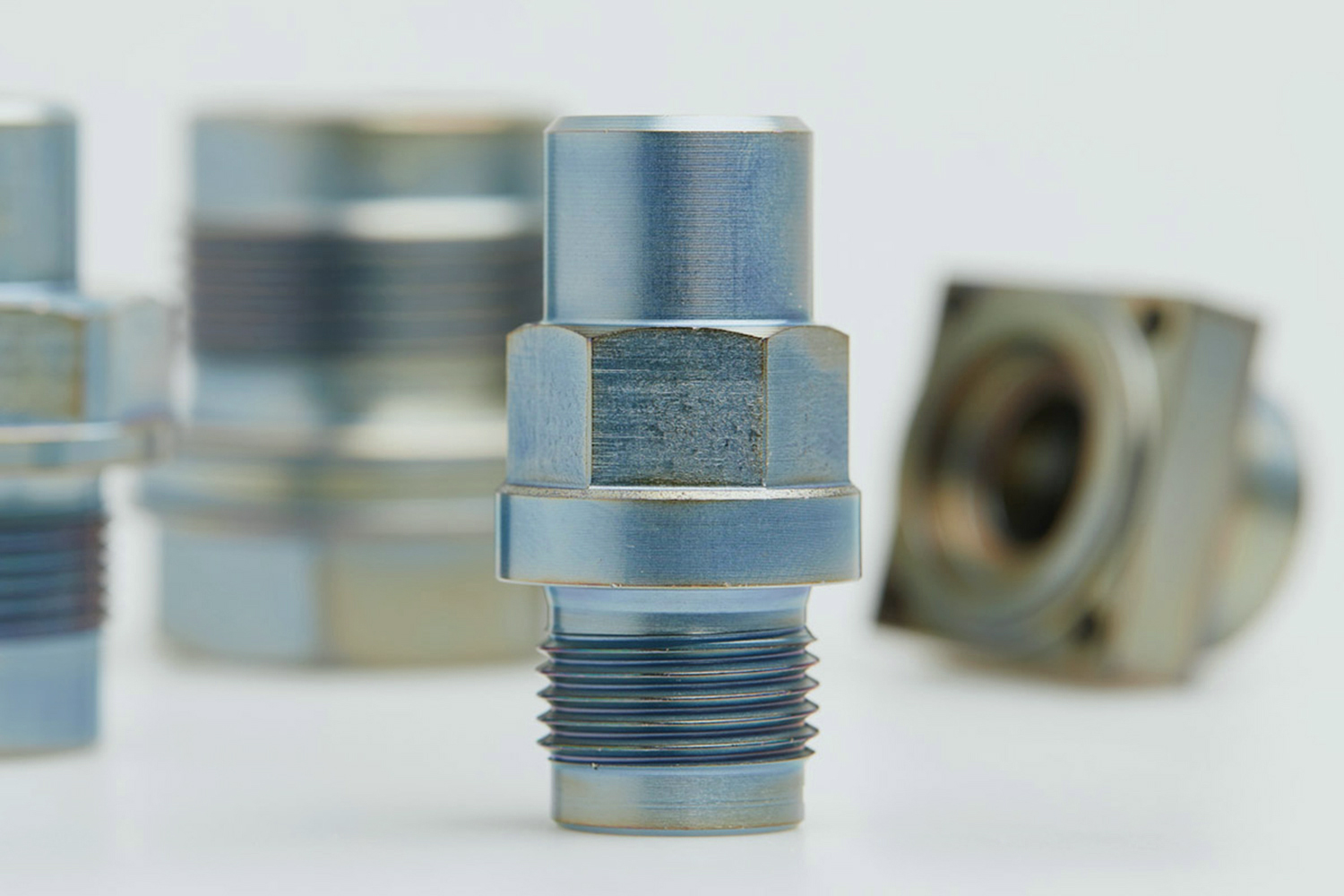

Zinc-Nickel

The coating we apply contains 10-15% nickel. This gives the layer system high cathodic corrosion protection, withstanding red rust for up to 720 hours in a salt spray test.

– Advantages

The applied layer contains 10-15% nickel, providing high cathodic corrosion protection and thermal resistance up to 120°C.

- Best corrosion protection against red rust

- Minimal formation of bulky corrosion products such as white rust

- Low contact corrosion with aluminum

- High-temperature stability

- Flexible surface

- Excellent throwing power, even for geometrically complex parts

- Coating according to DIN EN ISO 19598 (replacing DIN 50979)

– Applications

- Hydraulic components

- Mechanical engineering

- Aerospace

- Automotive

- Parts exposed to harsh environmental conditions

– Properties

Hardness: approx. 430-450 HV

Coating thickness: Zinc-nickel layers are typically applied in thicknesses between 5 and 25 μm. High corrosion protection is achievable from as little as 5 μm.

Passivation: Depending on requirements, the surface can be passivated in a metallic silver-gray or bluish-iridescent finish.

Temperature resistance: Up to 180°C

Nickel (chemical)

Wear and corrosion protection, along with high hardness, are the key advantages of a chemically applied nickel layer. The significant difference from electrolytic nickel is the contour-true layer buildup with a tolerance of ±2 μm.

– Advantages

Chemical nickel plating is a nickel-phosphorus alloy primarily used in functional applications but also suitable for specific food industry uses. This intricate yet fascinating technology has become a standard in many areas.

Certificates and test reports are available on the Downloads page.

– Applications

- Mechanical engineering

- Automotive

- Machine tools

- Medical industry

- Food industry (food safety declaration available under Downloads)

- Intermediate layer for high-performance chrome coatings

– Properties

Hardness: approx. 570 HV, up to 1000 HV after heat treatment

Coating thickness: 5-50 μm, depending on wear requirements

Phosphorus content: 9-12%

Wear resistance: approx. 25-35 mg/1000 revolutions (Taber Abraser CS 10)

Elastic modulus: 170-200 kN/mm²

Nickel (electrolytic)

The nickel layer is an ideal corrosion protection for non-ferrous metals. It also features wear resistance, solderability, weldability, polishability, and ductility. Nickel layers are often used as a base for chrome, silver, and gold coatings.

– Advantages

We offer the electrolytic nickel process in all variants, from matte to high-gloss finishes, and provide both rack plating and barrel plating methods.

– Applications

- Mechanical engineering

- Automotive

- Electrical industry

- Building & fittings industry

- Glossy intermediate layer for chrome/gold/silver

– Properties

Hardness: approx. 350 HV, depending on the electrolyte used

Coating thickness: 5-25 μm, depending on the requirement and component

Gold

Gold coatings feature high electrical and thermal conductivity and can also provide a flawless shine upon request. Whether for industrial or decorative purposes, a gold coating from Galvano Helbling adds significant value.

– Advantages

Our gold coatings are hard and abrasion-resistant. Depending on the coating thickness, the high purity of the precious metal ensures excellent corrosion protection.

– Applications

- Medical industry

- Electrical industry

- Decorative applications

– Properties

Hardness: approx. 150 HV

Coating thickness: customized to requirements

Silver

Silver is the whitest of all metals with high light reflection and exceptional electrical and thermal conductivity.

– Advantages

Unlike many other coating processes, the oxide formed on silver remains conductive. This makes silver coating highly suitable for electronic and electrical engineering applications. Our silver finishes are widely used for technical purposes and are also ideal for decorative use.

– Applications

- Electronics & electrical industry

- Building & fittings industry

- Reflectors & lamps

- Decorative applications

– Properties

Hardness: approx. 120 HV

Coating thickness: customized to requirements

Purity: 99.99%

Copper

Copper coatings can serve as an intermediate or final layer. They are primarily used as a base layer.

– Advantages

Simple copper plating is mainly used for decoration or as a base for coloring and patination. A prior copper layer is essential for nickel or chrome plating on zinc die casting. We can also color your parts to achieve the desired decorative look. Copper coating is available via rack plating or barrel plating at Galvano Helbling.

– Applications

- Decorative applications

- Intermediate layer for demanding base materials

Cadmium

Galvano Helbling continues to offer this rare process for selected applications. Due to its high toxicity, cadmium can only be used in specific industries.

– Advantages

Galvano Helbling is one of the few galvanizing providers in Switzerland that has long used cadmium plating for the aerospace industry. With years of collaboration with renowned clients, we bring extensive expertise. Depending on the risk class of the components, we also offer hydrogen de-embrittlement.

We are currently working on ISO-9100 certification and expect to be officially certified by mid-2020.

– Applications

- Aircraft Overhaul

- Aircraft Manufacturers & Suppliers